Using 3D Printed Optics for Fluorescence Microscopy

- Abstract number

- 63

- Presentation Form

- Contributed Talk

- DOI

- 10.22443/rms.mmc2023.63

- Corresponding Email

- [email protected]

- Session

- Early Career Symposium & RMS Early Career Committee AGM

- Authors

- Mr Jay Christopher (1), Dr Liam Rooney (2), Professor Gail McConnell (2), Dr Ralf Bauer (1)

- Affiliations

-

1. Department of Electronic and Electrical Engineering, University of Strathclyde

2. Strathclyde Institute of Pharmacy & Biomedical Sciences, University of Strathclyde

- Keywords

3D Printing, 3D printed optics, 3D printed microscopy

- Abstract text

Summary

A range of 3D printed lenses are developed for white light and fluorescence microscopy using a consumer grade 3D printer and spin-coating post-processing approach. The white light and fluorescence imaging performance of the printed lenses is compared against commercial counterparts. This opens the possibility for 3D printed optics research to be used in novel microscopy approaches benefiting from the flexibility of generating arbitrary lens surface shapes. Introduction Stereolithography (SLA) is an additive manufacturing technique which uses near-UV light to solidify liquid resin into the user defined design[1]. Desktop SLA printers are improving in their print resolution on a yearly basis, whilst maintaining budget friendly prices. This advances SLA manufacturing as an attractive technique for optical 3D printing, granting unique potential for low-cost freeform optics manufacturing[2,3] . Additionally, next to the potential to manufacture free-form lens geometries or unique sized optics, resin-based 3D printing allows swift replacement of optical components or even field repairs when necessary.

Materials and Methods

An Elegoo Mars 2 3D printer is used in combination with a clear photopolymerization resin (Formlabs Clear) to create spherical lenses. Three lens designs are tested: a f=20 mm, ½” diameter lens; and two 6 mm diameter lenses with f=10 mm and f=-6 mm focal lengths. Once printed, the lenses are washed in IPA and air dried before the curved side is spin-coated and cured with a transparent resin (VidaRosa UV resin). The planar lens side is subsequently placed onto a uniformly resin spin-coated glass slide and UV cured to create optical quality surfaces on both lens sides. Surface profiles and the surface roughness of printed lenses are evaluated using a white light interferometer (Veeco NT1100) and stylus profiler (KLA Tencor Alpha-Step). Two imaging systems are built to evaluate the 3D printed lenses of differing geometries. A white light transmission illumination setup is used to image a 1951 USAF target to benchmark the achievable contrast and resolution between the 3D printed lenses and their commercial counterparts. A further epifluorescence setup evaluates fluorescence imaging performance in multiple wavelength ranges. Imaging with a single lens and a combination of 4 lenses in a custom objective configuration (using convex, concave, and aspheric shapes) is compared.

Results and Discussion

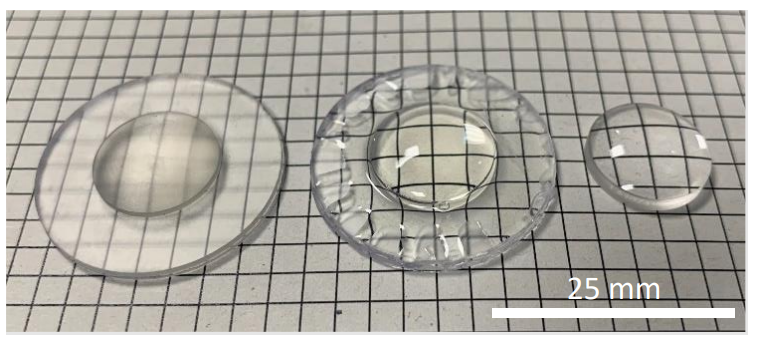

The measured surface profiles of the 3D printed lenses show a curved surface roughness below 200 nm on average, and planar surface roughness less than 30 nm. The 3D printed lenses radius of curvatures match their commercial counterparts within 6 % for all evaluated lens shapes (see Figure 1).

Figure 1 – Visual comparison of unprocessed 3D printed lens (left), postprocessed 3D printed lens (middle), and commercial glass lens (right).

White light brightfield imaging shows small differences in contrast uniformity between the 3D printed lenses and the glass polished commercial counterparts, however, the maximally obtained resolution for a single lens with 20 mm focal length is approximately 4 µm for the 3D printed lens and 2.5 µm for a commercial glass polished version. Using multiple of the 6 mm diameter 3D printed lenses in a custom objective configuration results in larger uniformity and resolution deterioration, with the performance still achieving similar resolution potential to its commercial multi-lens counterpart of below 2 µm. Fluorescence imaging of stained biological and materials specimens were acquired using the epifluorescence setup for both commercial and 3D printed lenses to analyse the wavelength dependent light transmission and potential auto-fluorescence impacts in achievable imaging performance.

Conclusions

3D printed lenses for microscopy applications are presented and evaluated. The performance in white light and epifluorescence setups is compared to commercial glass counterparts, as well as for using a single 3D printed lens relative to multiple 3D printed lenses in a custom objective configuration.

- References

References

[1] S. Zakeri, M. Vippola, and E. Levänen, “A comprehensive review of the photopolymerization of ceramic resinsused in stereolithography,” Addit. Manuf., vol. 35, page 1-3, 101177 (2020). DOI:10.1016/j.addma.2020.101177.

[2] N. Vaidya and O. Solgaard, “3D printed optics with nanometer scale surface roughness,” Microsystems Nanoeng., Vol. 4, no. 1, (2018). DOI: 10.1038/s41378-018-0015-4.

[3] G. D. Berglund and T. S. Tkaczyk, “Fabrication of optical components using a consumergrade lithographic printer,” Opt. Express, Vol. 27, no. 21, p. 30405-30420, (2019). DOI: 10.1364/oe.27.030405. Acknowledgements We acknowledge funding from the UK Engineering and Physical Sciences Research Council (grant EP/S032606/1, studentship EP/T517938/1), The Leverhulme Trust, and UK Royal Academy of Engineering (Engineering for Development Fellowship scheme RF1516/15/8).