Synthetic Graphite and xGnP composites for EMIS; relative to their platelet axis and platelet behaviour.

- Abstract number

- 350

- Presentation Form

- Submitted Talk

- Corresponding Email

- [email protected]

- Session

- Stream 5: Late Breaking

- Authors

- Miss Lina Jfairi (1)

- Affiliations

-

1. University of Manchester

- Keywords

- Electromagnetic Interference Shielding EMIS

- Synthetic Graphite

- xGnP Exfoliated Graphene Nano-platelets

- Injection mesh lay up

- Reflectance

- Alignment

- Platelet axis

- Magnetic stirring

- longer leaner cycle

- Abstract text

Summary- The aim of this project is to cross examine the platelet to platelet contact, and axis by means of standard exfoliation, magnetic stirring and sonication, to achieve conductive composites that are able to provide Electromagnetic Interference Shielding. However, conductance was not achieved. In contrast, the methodology of the manufacturing processes utilised do find that platelet axis can be adjusted.

Introduction- The background on the topic of EMIS is that there is a broad and extensive application of electromagnetic wave techniques used in an array of methods from military radar stealth, the EMIS of electronic devices and equipment and the means to which to provide protection from electromagnetic radiation (Jia et al., 2020) . As the use and development of the internet and electronic mediums grow, the volume of electromagnetic waves continue to grow and populate the environment. This direction of the rise of electromagnetic wave radiation challenge the research of EMIS towards the development of tetra-hertz (THz) applications. Traditionally, EMIS materials have been developed in the scope of wide bandwidth, high efficiency where these materials are required to be lightweight.

The objectives of this research are as follows:

1.To study the effects of graphene, graphite relating to volume and size of platelets on electrical conductivity or inversely, resistance.

2. To study the effects of heat, degassing, and mixing methods on the alignment of SG and xGnP platelets, with reference to platelet vacancies in composites.

3. To study the morphology of xGnP and SG nano-composites.

4. Study the impact of a longer, and leaner processing practice to preserve the platelet morphology (shape and size of the nano-platelets), using lower energy and speed in manufacturing.

The importance of this research is to study platelet behaviour, to have a better idea of platelet to platelet alignment and contact, so as to possibly provide EMIS through the analysis of the anisotropic property of graphite and graphene platelets. In order to shield or attenuate against EMI, the disruptive electromagnetic wave is required to absorb, reflect or dissipate this undesired interference. When the EMI is reflected it still exists as it has not been decayed or dissipated. The anisotropic property of the platelets is that they have different measurements in different directions, which may mean that graphite and graphene are able to reflect the EMI in a wide range of measurements and directions.

Methods - A mechanical stirrer was used in all experiments to provide standard exfoliation, and mixing. Graphite has magnetic properties; thus, a magnetic stirrer is used to see whether magnetism can be used to influence the alignment of the platelets, and to research whether the use of a magnetic stirrer affects the morphology of the platelets within the composites. A sonicator was used for degassing purposes i.e. to remove air pockets from the blend mix. The experiments conducted were to research the impact of a longer, leaner cycle /processing practice do preserve the platelet morphology (shape and size of the nano-platelets), using lower energy and speed in manufacturing.

An example of a manufacturing process used in this research is as follows:

Round 1: Mechanical Stirrer (90 m)-Magnetic Stirrer (90m) [either 30º or 40º] –Sonicator (45m) [either 30º or 40º]

Round 2: Mechanical Stirrer (60m)-Magnetic Stirrer (60) [40degree]-Sonicator (60)[40degrees]

Round 3: Mechanical Stirrer (30m)-Magnetic Stirrer (90) [34degree]-Sonicator (45m)[34degree]

Material- Two classes of exfoliated Graphene Nano-Platelets xGnP were used; M25 and C750 for the reinforcement of the blend mix of one set experiments. However, synthetic graphite SG with CAS Number: 7782-42-5 was used comparatively to the xGnP specimens. The epoxy matrix that was used in all experiments is the Axon Epolam 2017 resin and hardener epoxy.

Results and Discussion- Generally the composites exhibited very high resistance dominating over 100ohm. However, through the used manufacturing processes, it was possible to manipulate the platelet axis. This is probably the first step achieved towards a long journey of platelet alignment and contact. We have managed to observe the platelet light reflectance colours and behaviours under light microscopy.

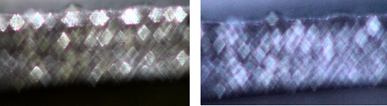

Fig 1. (a)Injection mesh lay up xGnP (b) beaker lay up synthetic graphite.

Here you can compare a beaker lay up of the blend mix into the moulds versus a syringe with 300 mesh wrapped at the tip for better alignment of the platelets lay up of blend mix into the moulds as well.

As it can be seen in Fig 1. (b) when using a beaker to lay up, air pockets within the composite are a lot more prevalent. Contrarily, Fig 1. (a) shows a more cohesive alignment of platelets. It must be said that this outcome still does not render the composites conductive.

Other interesting findings through the use of light microscopy to study the behaviours of the xGnP platelets.

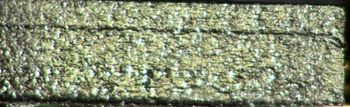

Fig 2. Side plane of composites using injection mesh lay up of xGnP.

The reflectance of platelets show some repetitive colours and shapes. Though the graphite and xGnP platelets are honeycomb in shape they are however showing a diamond sketch Fig 2. As this experiment outcome does use injection mesh lay up, the platelets do show linearity.

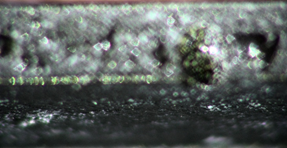

Fig 3.(a) Round 1 only: Magnetic Stirrer 40º, Sonicator 34º SG (b) Round 1,2 ,3 with the variable temperatures at round 1 being Magnetic Stirrer 40º, Sonicator 34º SG.

Here in Fig 3.(a) and (b) show a very high shine, and sheen reflectance. The reflectance of the platelets depict a very potent green sparkle. The visual inspection here is that the platelets have a gem stone like light reflectance with plenty of colour, and in the shape of a diamond.

Conclusion- In summary our findings were at first stage to obtain conductive composites using the reinforcement and matrix adopted in this research. Conversely, the research gap of 15% percolation maximum threshold, which if exceeded would render the epoxy composite very brittle. Therefore, it is necessary to understand the platelet axis properties to develop a means to manipulate the axis behaviour to obtain a good level of dispersion and platelet alignment, prior to achieving conductance .

- References

Jia, Z., Zhang, M., Liu, B., Wang, F., Wei, G. and Su, Z., 2020. Graphene Foams for Electromagnetic Interference Shielding: A Review. ACS Applied Nano Materials, 3(7), pp.6140-6155.