Correlative Tomography for micro- and nano- scale porosity reduction analysis in Additive Manufactured healable aluminium alloy

- Abstract number

- 329

- Presentation Form

- Submitted Talk

- DOI

- 10.22443/rms.mmc2021.329

- Corresponding Email

- [email protected]

- Session

- Stream 1: EMAG - Functional Materials

- Authors

- Mrs Julie Gheysen (3), PhD Bartlomiej Winiarski (2), Ali Chirazi (2), Adam Brinek (1), Mr Yifan Zhu (3), PhD Grzegorz Pyka (3), Prof. Aude Simar (3)

- Affiliations

-

1. Central European Institute of Technology, , Brno University of Technology

2. Thermo Fisher Scientific

3. Universite Catholique de Louvain

- Keywords

Correlative Tomography, L-PBF, aluminium, self-healing

- Abstract text

Aluminium alloys are widely used in aerospace and aeronautic industries because of their excellent strength-to-weight ratio. In these applications, overloads can occur, damage the part and lead to its replacement. In order to increase the part’s lifetime, a solution would be to use a material able to heal its damage and restore its continuity. The most advanced man-made self-healing materials are polymers. They are composed of encapsulated healing agents which are released when a crack propagates, leading to the crack closure [1]. Designing self-healing metals is more challenging because the damage is usually healed via solid-state diffusion, which cannot be triggered at room temperature. It requires a heat treatment to trigger the migration of the healing agents and allow the healing of these cracks and/or cavities [2]. However, the damage and its healing are hard to quantify using only surface observations. Additionally, due to a multiscale distribution of the microstructure and damage size, a multiresolution and multimodal imaging approach with a spatial resolution from micro- to nano- scale is required to evidence the microstructure healing efficiency. Correlative tomography (CMT) [3] is a concept/workflow of spatial registration in two and three dimensions (2D and 3D) of many imaging modalities - light microscopy (LM), electron/ion microscopy (EM, IM), X-Ray tomography, 2D/3D EBSD [2], EDS, Raman, etc.) - that allows various types of information, and at different length-scale, to be collected for the same region of interest (ROI).

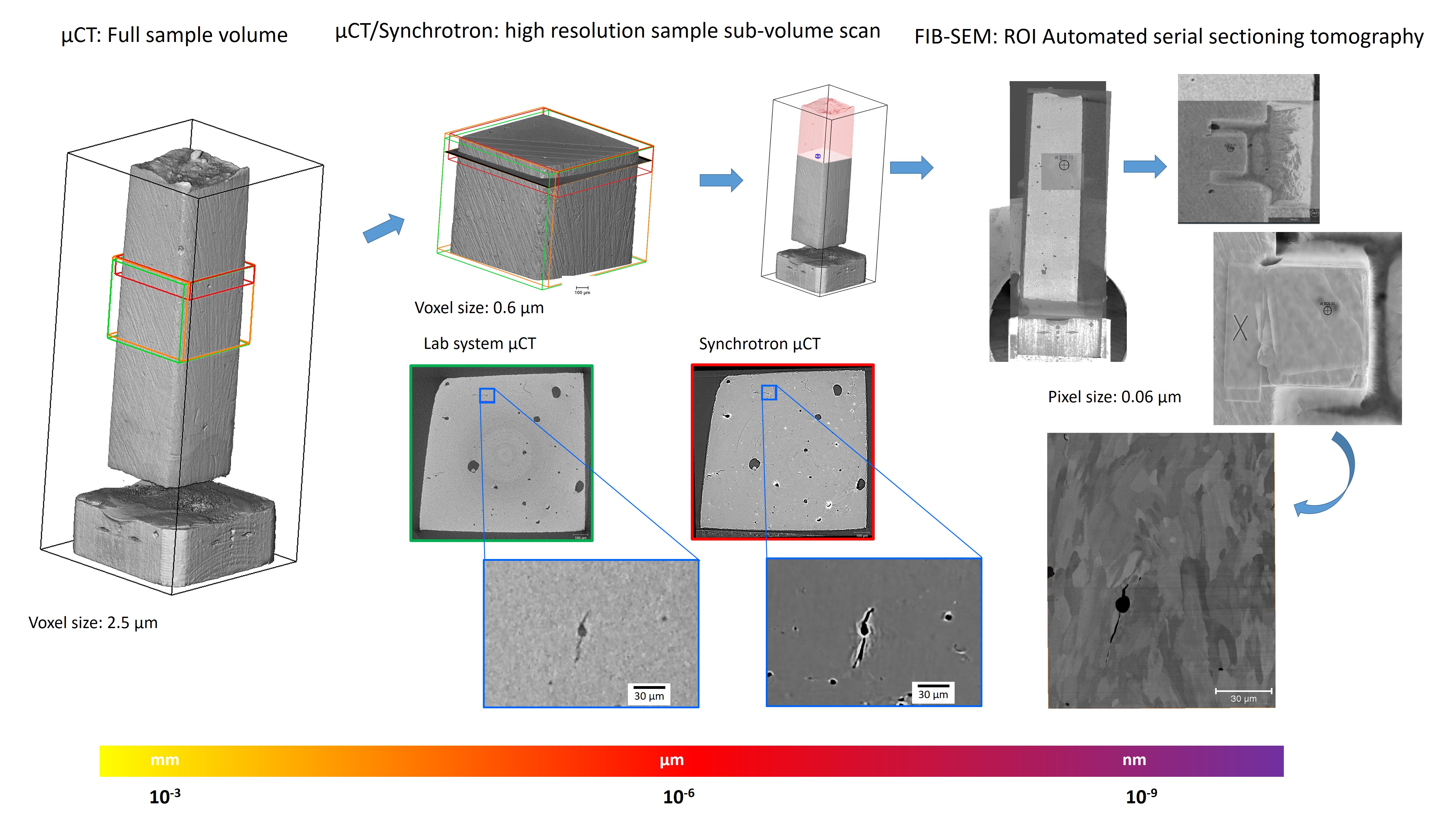

Therefore, the aim of this research was to develop a robust and controlled multiscale analysis protocol for evaluation of the cracks and pores dimensions within a healable AlMg alloy, using three-dimensional (3D) correlative microscopy/tomography. In this contribution, we utilized a non-destructive character of X-ray based imaging linked with high-resolution 3D volume analysis within PFIB-SEM via advanced correlative data acquisition and processing platform, available within Avizo software (Themo Fisher Scientific) [4].

Laser powder bed fusion (L-PBF) also called Selective laser melting (SLM) was used to manufacture a healable aluminium alloy. After the additive manufacturing process, the parts contained defects such as porosity and cracking. Therefore, a heat treatment was applied in order to restore the metallic continuity by melting the eutectic phase and its migration to these defects. Applied 3D data collection strategy required scanning, using µCT lab-based system (TESCAN XRE HR, Belgium) of a whole sample volume with voxel size of 2.5µm, in order to identify a sub-volume region for further investigation with higher resolution (0.6 µm voxel size) scan. Additionally, a pre-defined sample section has been investigated using TOMCAT beamline at Swiss Light Source SLS facility of Paul Scherrer Institute, providing high quality 3D data with 0.65 µm voxel size. After inspection of high resolution µCT data, a 100 µm3 volume region of interest (ROI) has been defined at a location indicating a characteristic defect. The specific ROI μCT data and sample surface SEM images have been co-registered in order to define the specific ROI coordinates within μCT images and trace it with the Plasma FIB-SEM via Maps-Avizo navigation and visualization software platform. Automated serial sectioning tomography (SST) has been performed at the specific sample location using the Xe Plasma FIB-SEM microscope (Themo Fisher Helios Hydra DualBeam, SST SEM back-scattered electron images with 60 nm voxel size) (Figure 1). Finally, data from FIB-SEM study were combined with μCT results using the visualization and quantification Avizo research platform. A critical defect type of a crack originating from the internal porosity has been traced with multi-resolution tomography approach (Figure 1) with precision of 5 µm. High quality synchrotron tomography results revealed presence of micro-pores in surrounding of the crack origin. μCT data guided applications of PFIB-SEM system in the workflow allowed in excess hundreds of microns size cross-sections in all dimensions, and SEM recording of nano- sized microstructural features at the identified ROI. The details of the L-PBF microstructural features efficiency have been evidenced thanks to post-tomography correlation with PFIB-SEM nano-scale 3D information. These preliminary results indicate that the correlative microscopy approach for acquisition of the serial multi-resolution tomography data correlated with FIB-SEM tomography allow for precise location and characterisation of the critical defects. Furthermore, investing as built sample with multiscale tomography approach followed by extended correlative imaging of the same location at the heat-treated sample can lead to better understanding and quantification of the healing mechanism.

Figure 1. Correlative microscopy approach used in the current study.

- References

[1] Ghosh, S. Wiley, 2009.

[2] Arseenko, M., et al. ICSHM, 2019.

[3] Burnett, TL., et al. Scientific Reports 4, 2014

[4] Winiarski, B., et al. Microsc. Microanal. 25 (Suppl 2), 2019