Heat Treatment of Steel: A Novel High Temperature In Situ SEM Imaging Approach.

- Abstract number

- 284

- Presentation Form

- Submitted Talk

- DOI

- 10.22443/rms.mmc2021.284

- Corresponding Email

- [email protected]

- Session

- Stream 2: EMAG - In-situ microscopy

- Authors

- Ms Rhiannon Heard (1, 2)

- Affiliations

-

1. University of Oxford

2. Natural History Museum

- Keywords

Carbon Steel

Heat Treatment

SEM

In Situ

Oxidation

Phase Transformation

Grain Growth

- Abstract text

Summary

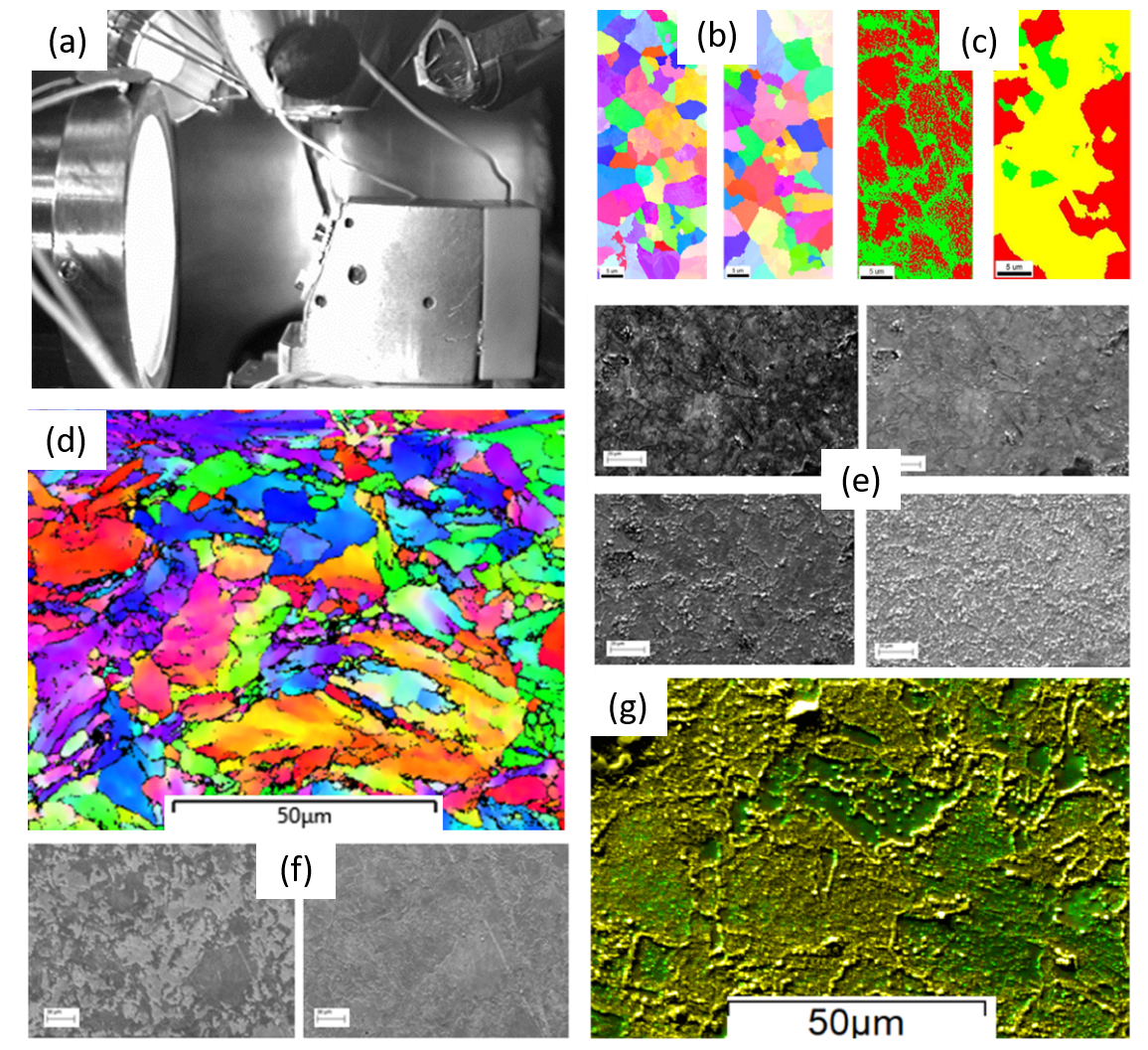

The development of a new heat stage that can be used within a commercial Scanning Electron Microscope (SEM), has facilitated Electron Backscatter Diffraction (EBSD) and Secondary Electron (SE) imaging at temperatures up to 920 °C. The recent studies focus on the heat treatment of Steel and aim to demonstrate the effects of surface finish and oxidation on the ability to track surface microstructural changes, representative of the bulk of the specimen, at these temperatures in situ. The applications focus on evaluating grain growth, phase change and oxidation oxide formation of Steel using novel in situ thermal etching SE and EBSD imaging supplemented by other microscopy techniques. These unique observations document grain growth and phase transformation patterns, which provide in-sight into the microstructural changes that occur during heat treatment. Thus, the data enhances the understanding of the heat treatment process of Steel whilst highlighting the benefit of in situ high temperature testing for providing information on grain boundaries, crystallography and phase changes, as well as demonstrating the success of this new heat stage.

Introduction

In situ high temperature SEM imaging enables observation and subsequent quantative and qualitative analysis of material microstructural behaviours. Recent development of a novel heat stage [1], has focussed on understanding how surface observations at high temperature, may represent the microstructural evolution within the bulk of the specimen. Hence, this study demonstrates the parameters required to ensure the images captured using novel heat stages developed for experimental in situ high temperature SEM imaging are representative of the equivalent ex situ dynamic process. The results of the investigation are subsequently used to study the microstructural evolution, with respect to grain, phase and oxidation, during the heat treatment process of Carbon Steel.

Method

Experiments were conducted using 0.4% carbon steel with imaging up to 920 °C capturing grain and phase developments during heat treatment. The high temperature SE and EBSD imaging was made possible owing to the use of a novel heat stage within a Zeiss EVO (E)SEM. From the SE images it was possible to track the grain growth and morphological transformation at temperature owing to a phenomenon known as thermal etching [2]. The SE data was further supplemented by high temperature EBSD data capture during the heat treatment. To support the in situ microstructure data gathered, chemically etched samples were imaged optically before and after heating and change in composition quantified.

Results & Discussion

The in situ high temperature thermal etching technique was used to study the microstructural evolution of Carbon Steel during normalising heat treatment. To ensure the surface data observed was representative of the bulk of the specimen, the microstructural evolution ex-situ after specimens underwent thermal etching was also considered for different temperatures. The grain growth ex-situ at the surface and bulk post a 4-hour heat treatment at 800, 850 and 920 °C indicate a negative correlation between temperature and surface grain growth, but a positive correlation between temperature and bulk grain growth. This is due to oxidation rate increasing with temperature where the oxidation pins the grain boundaries around the thermal etch on the surface, stalling grain growth, indicating surface may not always represent the bulk. However, oxidation is minimal when heating for 1 hour at 800 °C and thus in situ surface grain growth is representative of the bulk of the material. Therefore, for heat treatments of Carbon Steel which were less than 1 hour at 800 °C, in situ SE and EBSD data was used to quantify grain growth and phase transformation. Calculating in situ grain growth indicated abnormal linear grain growth occurred, which may be due to some remaining ferrite grains shrinking as austenite grows [3]. Phase change data suggested the formation of the austenite phase during heat treatment from a ferrite/pearlite starting structure occurs by a combination of nucleation and growth with initial transformation of the pearlite phase followed by the ferrite. The SE data was supported by EBSD phase change data. For higher temperatures, oxidation during heat treatment was tracked, where the SE in situ observations provided insight into the morphological formation of surface oxidation during heat treatment of Carbon Steel [4].

Conclusion

In situ high temperature imaging is highly beneficial in tracking and quantifying changes in phase and microstructure but is affected by surface finish and oxidation. The data shown here provides insight into the effect of heat treatments on the bulk verses surface of a material and how sample preparation and atmosphere can impact this. However, if oxidation on the surface is limited, thermal etching SE results demonstrate an alternative technique to monitor changes in microstructure in situ at temperature. Finally, the data establishes the ability of the new stage to image at temperature and the benefits of capturing microstructural evolution in real time during heat treatment processes.

Figure: (a) heat stage in situ, (b) EBSD Inverse Pole Figure Map of Carbon Steel pre heat treatment and at 800 °C, (c) EBSD Phase Map of Carbon Steel pre heat treatment and at 800 °C, (d) EBSD Inverse Pole Figure Map of Carbon Steel post heat treatment, (e) SE high temperature images of Carbon Steel at 920 °C at regular intervals up to 1 hour, (f) SE high temperature images of Carbon Steel at 800 °C after 5 minutes of heating and 20 minutes and (g) EDX compositional map post heat treatment of Carbon Steel where green is Iron and Yellow is Oxygen.

- References

[1] E. W.-B. and K. D. Rhiannon Heard, John E. Huber, Clive Siviour, Gary Edwards, “An investigation into experimental in-situ SEM imaging at high temperature.,” Rev. Sci. Instrum., 2020.

[2] W. W. Mullins, “Theory of Thermal Grooving,” vol. 333, no. 1957, 1986, doi: 10.1063/1.1722742.

[3] R. HEARD, K. I. DRAGNEVSKI, and C. R. SIVIOUR, “In‐situ SEM observation of grain growth in the austenitic region of carbon steel using thermal etching,” J. Microsc., p. jmi.12894, Apr. 2020, doi: 10.1111/jmi.12894.

[4] R. Heard, C. R. Siviour, and K. I. Dragnevski, “In situ SEM analysis of surface oxidation mechanisms in carbon steel during vacuum heat treatment,” Mater. Today Proc., Jun. 2020, doi: 10.1016/j.matpr.2020.05.396.