Characterizations of Responsive Photonic Liquid Crystal Network Coatings on Flexible Plastic Substrates by Atomic Force Microscopy

- Abstract number

- 44

- Presentation Form

- Poster Flash Talk + Poster

- DOI

- 10.22443/rms.mmc2021.44

- Corresponding Email

- [email protected]

- Session

- Poster Session 2

- Authors

- Dr. Lanti Yang (1), Dr. Nadia Grossiord (3), Dr. Ellen van Heeswijk (2), Prof.Dr. Albertus Schenning (2)

- Affiliations

-

1. 1. Technology & Innovation, SABIC

2. 2. Department of Chemical Engineering and Chemistry, Eindhoven University of Technology

3. Technology & Innovation, SABIC

- Keywords

AFM-QNM, Responsive Photonic Liquid Crystal Network, Flexible Plastic Substrates, modulus mapping

- Abstract text

Summary This abstract highlights a novel Atomic Force Microscopy (AFM) approach to gain valuable insights into various liquid crystal networks (LCN) on plastic substrates. Studies using AFM-quantitative nanomechanical mapping (AFM-QNM) for the LCN alignment, adhesion to plastic substrates and the nano-mechanical properties of the LCN coating characterizations are described. The results accelerate the design and development of various responsive LCN on flexible plastic substrates for a variety of applications.

Modifications to add stimulus-triggered functionality to surfaces have enabled many new advances such as self-healing, thermal regulation, energy scavenging, sensing and anti-(bio)fouling. In particular, coatings based on cholesteric liquid crystal networks (LCN) are versatile materials to create stimuli-responsive coatings onto plastic substrates, which lead to lightweight and flexible applications, notably in healthcare [1, 2]. During the design and application of stimuli-triggered LCN coatings on plastic substrates, the main challenges are 1) coating adhesion to the substrate; 2) cholesteric liquid crystal alignment, which governs the (optical) properties of the functional coating; 3) combination of both responsiveness and mechanical wear resistance and 4) response specificity and sensitivity towards a stimulus. Therefore, to assist the design and development of such a coating system on plastics, advanced characterizations for both a thorough understanding of the LCN coating morphology and quantifying the coating mechanical properties are crucial. Here, we present a new method based on AFM-QNM in combination with a neat sample preparation procedure for multiple LCN coatings on plastic substrates characterizations.

Several films with LCN coatings on flexible plastic substrates were prepared using a protocol described in Ref. 3. For the film cross-section characterizations, the films were first cut to a suitable size and subsequently carefully sandwiched between two supporting plastic sheets. The whole was then cryo-microtomed at -120°C with a LEICA EM UC7 microtome to obtain a nano-scale flat cross-sectional surface. All AFM measurements were performed on a Dimension FastScan AFM system (Bruker) AFM using high-accuracy quantitative nanomechanical mapping mode (AFM-HA-QNM) with a frequency of 0.7 Hz. The AFM tip had a spring constant of 40 N m−1 (Bruker, RTESPA-300-30). To understand the nanomechanical properties with LC coatings with different crosslinking degrees, the elastic modulus of the sample was fitted from the force curve using the Derjaguin–Muller–Toropov (DMT) model referencing a polycarbonate calibration sample with a known modulus of 2.6 GPa.

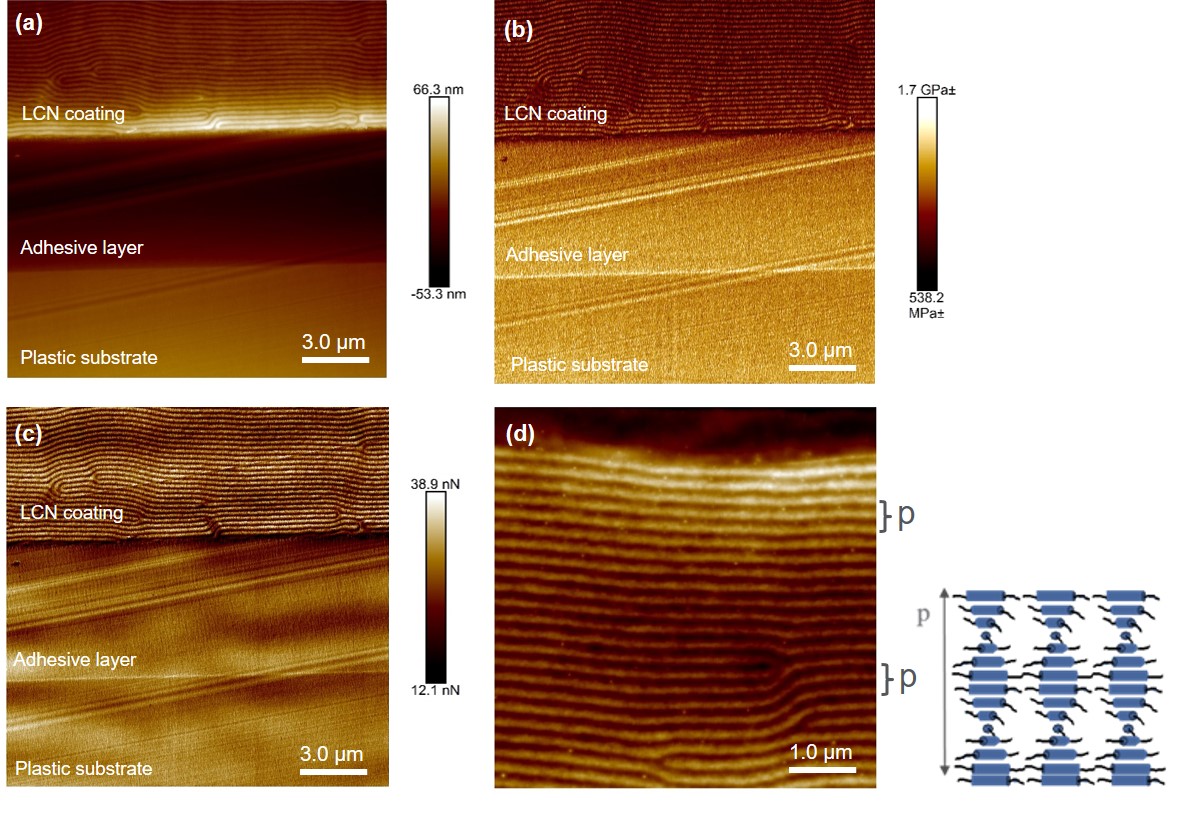

When (helix-shaped) cholesteric LCPs are oriented perpendicularly to a substrate, periodic changes of the refractive index due to the LC orientation change result in the creation of parallel planes of which the properties are described by Bragg’s law. Consequently, the pitch (p) of the helix changes due to intercalation of molecules or thermal expansion, which results in a shift of the reflection band and therefore a change in terms of optical properties. Since controlled LCN alignment is directly correlated to the optical properties of the coating, it is critical to be able to assess the alignment at different locations of the coating. Imaging the alignment of LCN can be a challenge for electron microscopy imaging due to the low material contrast difference. However, AFM-QNM high resolution imaging was able to clearly identify LCN alignment in our samples (Fig.1). Clear parallel lines in the LCN coating layer are well visualized in the images. The images also show a constant parallel alignment with the same pitch size at different locations of the LCN coating. Furthermore, the modulus and adhesion mapping images provide information on the viscoelastic properties of the LCN coating, the plastic substrates and an applied adhesion layer. The results also help assess the interface between different layers. More details of the interface characterizations on different design systems will be shown in the presentation. In short, the study demonstrates that using an adhesion layer between LCN and plastic substrates as shown in Fig. 1 can strengthen interlayer adhesion.

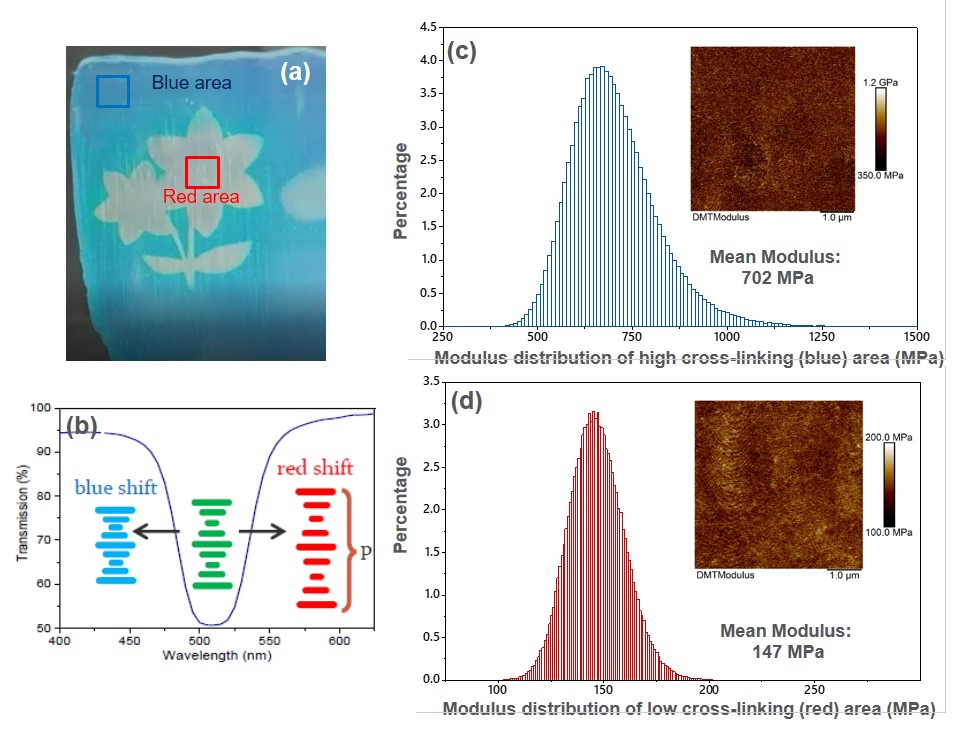

In the coating system shown in Figure 2, the mechanical properties such as flexibility and swelling behavior of the network play vital roles on the network’s responsive behavior. The responsiveness and color of LCNs are controlled by changing the cross-linking density and molecular weight. The designed system opens a new route to tune the functional (optical) and responsive properties with specificity and sensitivity. Here, AFM-QNM characterizations played a crucial role to indisputably prove these points, by enabling direct correlation and quantification of the relationship between coating color, cross-linking density and elastic modulus [3].

In conclusion, a novel AFM approach was developed to characterize various LCN coatings on plastic substrates. The characterizations provided valuable information on LCN alignments, adhesion to plastic substrate, and mechanical properties. Furthermore, our approach contributed to the in-depth understanding of the factors governing the stimulus-triggered response of the LCN coatings. This research therefore helped to solve the main challenges of designing stimuli-triggered, light weight and flexible LCN coatings on plastic substrates.

Figure 1 AFM-QNM images to demonstrate the LCN coating on Plastic substrate using an adhesive layer. The images are from different signal channels with (a) height image, (b) modulus mapping image, (c) adhesion mapping image. A high magnification AFM height image in the LCN coating area is shown in (d) to demonstrate the pitch size with a schematic drawing of LCN alignment.

Figure 2 A) Photo of the patterned coating. The color boxes indicate the high-crosslinking (blue) and low-crosslinking (red) areas of the LCN coating areas used for AFM measurements. (b) Schematic drawing to demonstrate the pitch size changes in the reflection color shift. (C) the modulus distribution of high-crosslinking area with an inserted modulus mapping image (D) the modulus distribution of low-crosslinking area with an inserted modulus mapping image.

- References

References:

[1] T. J. White, D. J. Broer, Programmable and adaptive mechanics with liquid crystal polymer networks and elastomers Nat. Mater., 2015, 14, 1087.

[2] E. P. A. van Heeswijk, A. J. J. Kragt, N. Grossiord, and A. P. H. J. Schenning, Environmentally-responsive photonic polymers Chem. Commun., 2019, 55, 2880.

[3] E. P. A. van Heeswijk, L. Yang, N. Grossiord, A. P. H. J. Schenning, Tunable Photonic Materials via Monitoring Step-Growth Polymerization Kinetics by Structural Colors, Adv. Funct. Mater., 2020, 30, 1906833