A Modular 100 keV Vacuum Sealed FEG for High-resolution Microscopy

- Abstract number

- 366

- Presentation Form

- Submitted Talk

- Corresponding Email

- [email protected]

- Session

- Stream 5: Late Breaking

- Authors

- Professor Mohamed El-Gomati (2), Mr Torquil Wells (2), Dr Xiaoping Zha (2), Mr Richard Sykes (2), Dr Christopher Russo (1), Dr Richard Henderson (1), Dr Greg McMullan (1)

- Affiliations

-

1. MRC Laboratory of Molecular Biology

2. York Probe Sources Ltd

- Keywords

Transmission Electron Microscopy (TEM), Field Emission Gun (FEG), 100 keV, Cryomicroscopy, CryoEM, Structural Biology (SB)

- Abstract text

M. M. El-Gomati*, T. Wells, X. Zha, R. Sykes, C.J. Russo**, R. Henderson**, and G. McMullan**

York Probe Sources Ltd, York, UK

*Department of Electronics, University of York, Heslington York, YO10 5DD, UK

**The MRC Laboratory of Molecular Biology, Francis Crick Avenue, Cambridge, CB2 0QH UK

Summary

A modular standalone 100kV field emission gun (FEG) has been developed to operate on a standard TEM electron optical column or custom-designed High Voltage (HV) electron optical columns. The FEG comprises a Schottky Field Emitter (SFE) and an electrostatic Einzel lens that can operate from 20-100kV, in an ultra-high vacuum (UHV) chamber. The FEG is transported under UHV for integration on the instrument column. This will allow cost-effective improved performance for applications such as electron cryomicroscopy, electron beam lithography as well as other applications.

Introduction

The optimum electron beam energy in electron cryomicroscopy has been the subject of debate. Recent studies have found that an electron beam energy of 100 keV is preferable to higher beam energies in terms of the useful information obtainable from single-particle biological specimens [1,2]. Similar beam voltages have also been called for in electron beam lithography and materials science applications [3,4]. A dedicated modular field emission electron gun (FEG), operational to 100 kV to address such needs as well as other laboratory-based novel applications, is reported here.

Methods and Materials

The FEG comprises a SFE cathode and an electrostatic Einzel lens, operational between 20 and 100 keV. It can independently focus the beam into the lower electron optical column with a range of beam currents in the range 20 nA to 200 nA at an angular current intensity in the range of 300 mA/str, depending on the cathode configuration. The FEG vacuum chamber occupies a physical envelope approximately 210 mm diameter and 315 mm in height (in addition to the plug and cable). The vacuum chamber maintains a base pressure of <2x10-10 mbar, and the chamber is designed to be valved off to atmosphere using a manual isolation valve. This allows the FEG chamber to maintain UHV during transport to facilitate either, a fast exchange of a used emitter, or during maintenance of the lower electron column, thus reducing instrument downtime. During operation a differential aperture in the FEG vacuum chamber allows a pressure differential of >10-2 mbar to be achieved between the FEG and the lower interface vacuum chamber, thus allowing safe and stable operation of the FEG SFE.

To drive the FEG, a standalone, high stability 100 kV power supply unit (PSU), together with a plug and cable and a vacuum feedthrough, have also been developed. The PSU outputs for the operation of the FEG electrodes float on the beam potential with voltage ripples of less than 1 ppm. An advantageous feature of this design is that the feedthrough and the high voltage plug assembly do not require the use of SF6 gas, as is common with the high voltage FEGs. This allows an easier ‘hot swap’ transition for emitter exchange, reducing instrument downtime.

Results and Discussions

In its current configuration, the FEG has spherical and chromatic aberration coefficients (Cs and Cc respectively) in the range of, Cs = 45 to 55 mm; and Cc = 25 to 27 mm, at 100 keV over a range of working distances of 10 mm to 60 mm from the exit plane of the FEG unit.

Operation of the FEG has been demonstrated on a JEOL JEM-1400 TEM and Tecnai T12 TEM, whereby the original W hairpin source, the electron gun chamber and EHT unit were replaced with the aforementioned FEG unit. The sealed FEG chamber was installed on the column under a base pressure in the range of <2x10-10 mbar. To maintain UHV during operation, an intermediate vacuum chamber was added, to interface between the FEG chamber and the column and evacuated with an IGP to 10-8 mbar.

Preliminary results show an electron beam current stability of <1% drift over 24 hours and <0.5% over 1 minute for operation in the voltage range of 30 to 100 kV. Gold fringes in images of gold nanoparticles have been resolved confirming a resolution limit of better than 0.235 nm at 90 keV, see Figs 1-2.

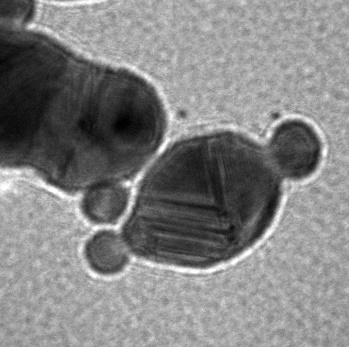

a)

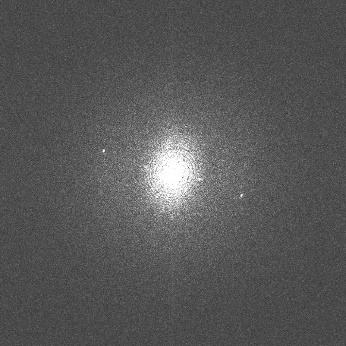

b)

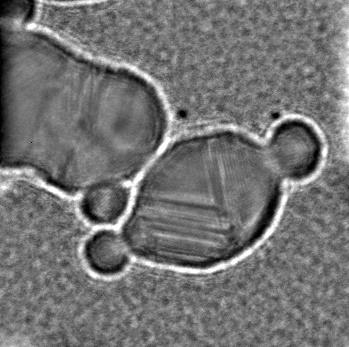

c)

Figure 1: Bright field image of gold particles on amorphous carbon at 90 keV using modular FEG source, on a JEM1400 column. Nominal magnification was 400 kx on phosphor coupled CCD detector (Gatan Ultrascan 1000) binned 2 x 2 pixels, with exposure time 4 s using a beam current of 1100 pA uniformly illuminating a region slightly larger than the image. Panel a is the original image, b is the FFT of the original image and, c shows the inverse FFT of the masked FFT.

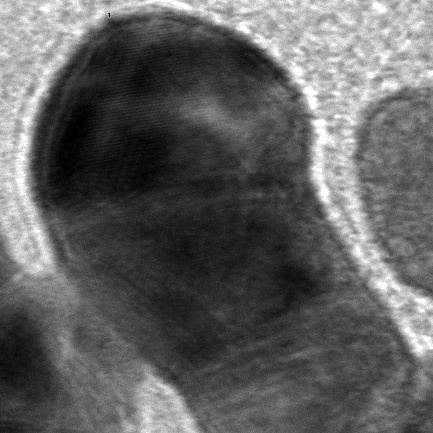

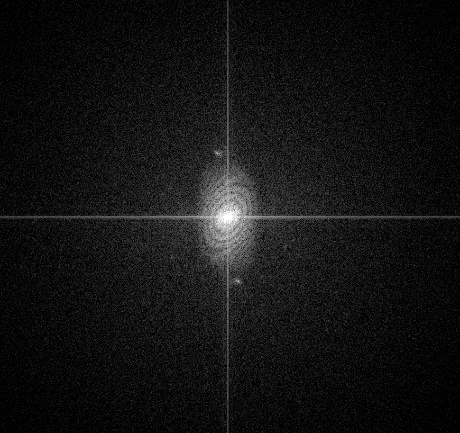

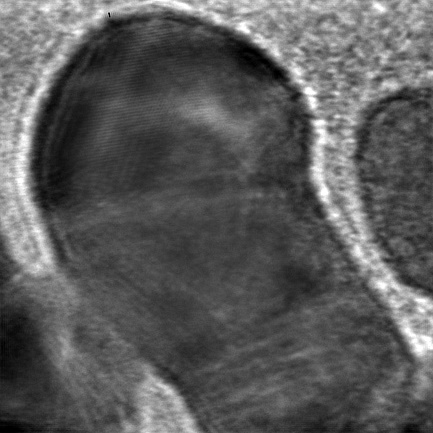

a)

b)

c)

Figure 2: Bright field image of gold particles on amorphous carbon at 90 keV using modular FEG source, on a Tecnai T12 column. Nominal magnification was 570kx on phosphor coupled CCD detector (Gatan Ultrascan 1000) binned 2 x 2 pixels, with exposure time 2 s, beam current of 1100 pA uniformly illuminating a region slightly larger than the image. (a) is the original image, (b) is the FFT of the original image and, c) shows the inverse FFT of the masked FFT.

Conclusions

The present design lends itself to integration onto existing high voltage electron columns, such as upgrading thermionically-operated Transmission Electron Microscopes (TEMs) or Electron Beam Lithography (EBL) systems into FEG operation, as well as other R&D applications.

Acknowledgments:

The present development has been partly funded with a generous grant from Innovate UK (Project No. 103806) and support from the Medical Research Council under grants MC_U105184322 and MC_UP_120117, Wellcome Trust Grant 220526/B/20/Z and EPSRC R122522.

- References

References:

1. M.J. Peet, R. Henderson & C.J. Russo “The energy dependence of contrast and damage in electron cryomicroscopy of biological molecules” Ultramicroscopy 203, 125–131 (2019).

2. K. Naydenova, G. McMullan, M.J. Peet, Y. Lee, P.C. Edwards, S. Chen, E. Leahy, S. Scotcher, R. Henderson, C.J. Russo “CryoEM at 100 keV: a demonstration and prospects” IUCrJ 6, 1086-1098 (2019).

3. M. Kamp, M. Emmerling, S. Kuhn, and A. Forchel “Nanolithography using a 100 kV electron beam lithography system with a Schottky emitter” J. Vac. Sci. Technol. B 17, 86–89 (1999).

4. R.F. Egerton “Choice of operating voltage for a transmission electron microscope” Ultramicroscopy 145, 85–93 (2014).